Technical & Compliance Troubleshooting Support

Technical and compliance issues can cause product failure, regulatory non-compliance, certification delays and costly operational disruptions. We help manufacturers identify root causes and implement corrective actions quickly and effectively.

Our troubleshooting service covers both technical formulation issues and regulatory compliance concerns.

Areas We Support

Raw Material Issues

- Heavy metals contamination

- Microbial growth

- Unstable ingredients

Formulation & Stability

- Product separation

- Taste/smell change

- Incompatibility

Test Result Failure

- Failed microbiological test

- Out-of-spec analysis

- Ad-hoc rejection

Production Process & Hygiene Compliance

We help resolve technical issues related to production process deviations and hygiene control that may impact product quality or certification compliance.

- Corrective actions for swab test failures

- Sanitation inconsistencies

- Process non-conformities

Regulatory Findings

- Non-compliance during audit

- Warning letters

- Rejection of registration

How We Solve It

- ✔ Technical issue evaluation and root cause analysis

- ✔ Review of documentation and laboratory test results

- ✔ Recommendation for test repetition or additional analytical studies

- ✔ Guidance on formulation modification or supplier replacement

- ✔ Development of corrective and preventive actions (CAPA)

- ✔ Support internal team during improvement implementation

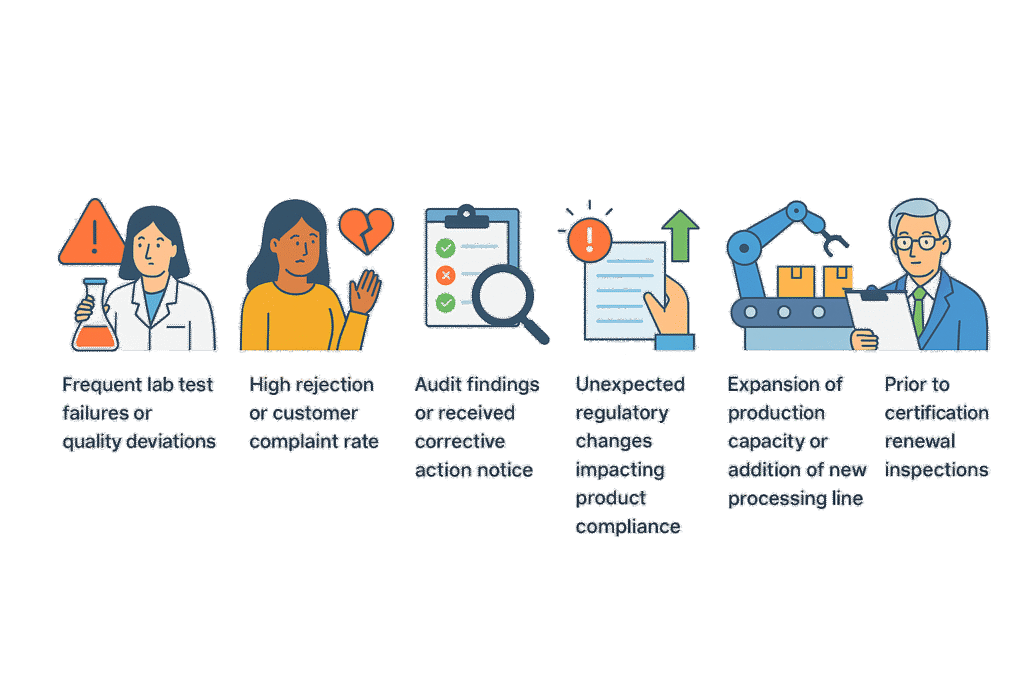

When to Use This Service

- Frequent lab test failures or quality deviations

- High rejection or customer complaint rate

- Audit findings or received corrective action notice

- Unexpected regulatory changes impacting product compliance

- Expansion of production capacity or addition of new processing line

- Prior to certification renewal inspections

Engagement Options

- One-time troubleshooting or technical intervention project

- Ongoing compliance support under retainer partnership

- Factory investigation and written risk assessment report

- Pre-audit gap analysis (technical and regulatory)

Why Work with Us

- ✔ Extensive experience resolving complex compliance challenges

- ✔ Successfully addressed contamination and formulation issues resulting in approved registrations

- ✔ Practical, solution-based approach combining testing, production and regulatory perspectives

- ✔ Faster problem resolution compared to internal investigation alone

Trusted by Customers

We encountered a serious problem during our Halal application when our previous consultant became uncontactable after the process had begun. As a result, our application was rejected by JAKIM. Fortunately, we engaged VCARE 2U (Mr. Cheah), who took over the process professionally and guided us through every requirement. With their support, we successfully obtained our Halal certification.

KWT

We initially engaged this company for their laboratory testing services for our corn products. As our business grew, we required HACCP certification to support our expansion. The company provided comprehensive guidance throughout the application process, enabling us to become the first frozen corn products processing facility in Malaysia to receive HACCP certification from KKM.

Joe

Our herbal products showed heavy metal contamination, so we retested with VCARE 2U. The results were confirmed, and Mr. Cheah helped us trace the contamination back to our raw materials and plantation site, then advised us on corrective actions. He later assisted us in getting our product registered with NPRA and obtaining the MAL number.

MBL